Significance and Types of LED PCB

Affordable and durable lighting sources are preferred in modern home and commercial lighting systems. Because of its efficiency and output lumens, LED lighting systems are the favored option for residential, automotive, and outdoor lighting systems. A power circuit is included in the printed circuit board on which LEDs are installed. Due to their propensity to generate excessive heat, LED PCB designs are distinct from conventional circuit board designs. Aluminum PCB material, heat sinks, and other structural components are used in LED PCB China design to remove thermal energy from the lighting board. The difficulties, factors, and varieties of LED PCB design will be covered in this article.

The Use of LED PCBs

The basis of LED lighting systems is LED PCBs. The advantages of using LED light sources are as follows:

- Compact size: LEDs' small size makes them useful in products like computers, cellphones, cars, floodlights, and traffic lights.

- Lower power consumption: To save energy, the majority of home lighting employs LED. About 80% less electricity is used while using LED lights.

- Longer longevity: Compared to traditional light sources, LEDs have a lifespan that is 25 times longer.

- Mercury-free: Because traditional bulbs contain mercury, they have a significant negative environmental impact and must be disposed of carefully. Since LEDs don't contain mercury, they may be readily disposed away and do less environmental damage than conventional lights.

- Efficiency: LEDs create less heat than incandescent lighting. LED lights use their energy consumption for lighting rather than heating.

90% of the energy used by conventional bulbs is released as heat. About 20% of the total energy consumed by LEDs goes toward heat dissipation. However, LED circuits are seriously endangered by heat production of even 20%. When designing LED PCBs from LED PCB manufacturer, certain issues must be resolved.

Many LED PCB types

Typical LED PCB design types include:

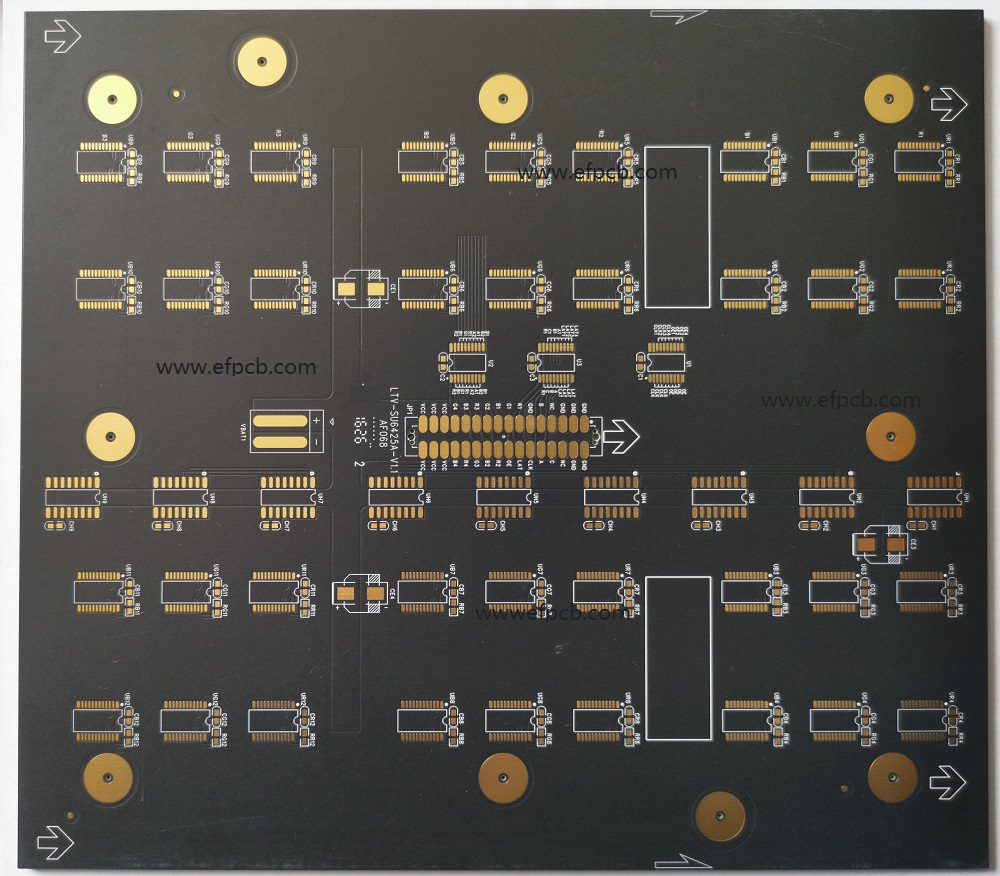

- Single-sided LED PCBs - Single-layer LED PCBs work well for straightforward circuitry.

- Double-sided LED PCBs - Two-layer PCBs can be utilized for increased stability, heat dissipation, and current handling capacity. Both through-hole mounting and surface mount techniques can be used to install components on double-sided PCBs.

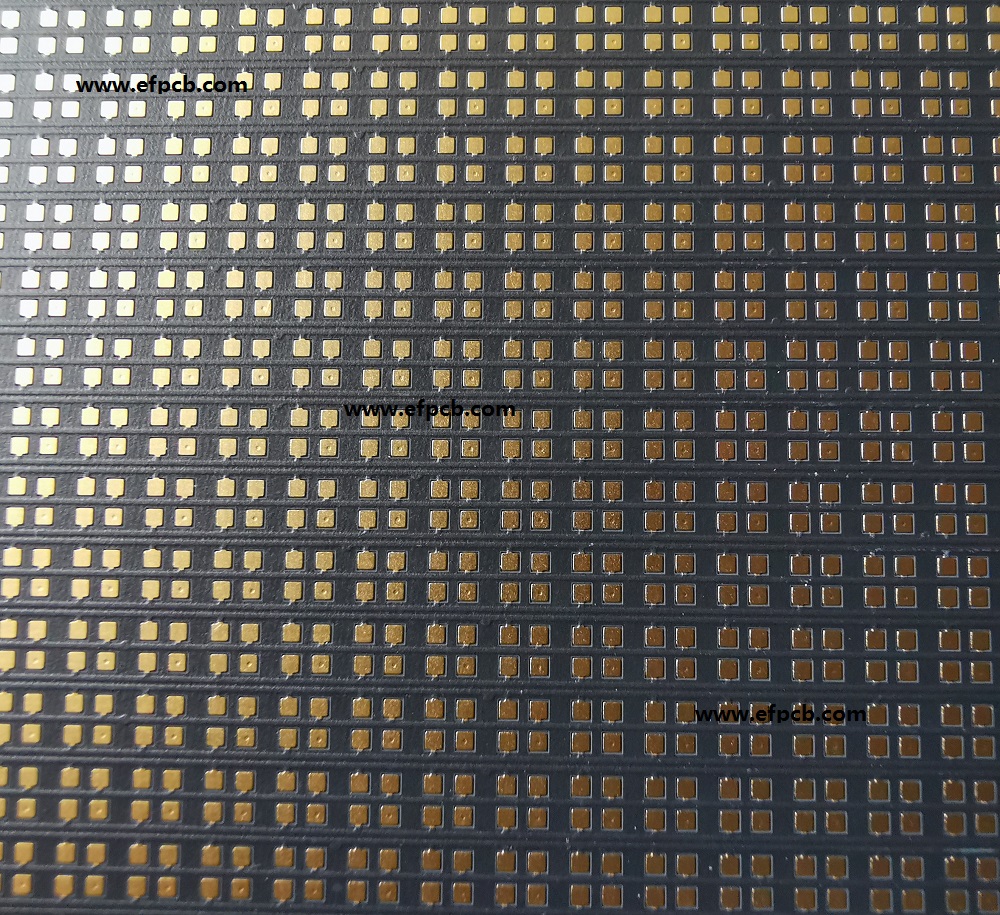

Multilayered LED PCBs -

Multilayer PCBs are the finest for building sturdy hardware LED lighting

systems. LED PCB China is created as multilayer boards as the

number of connections and circuit complexity rise.