Interposer board: Intermediate PCB Device with High Performance

An Interposer board is a switching product using a PCB board as a form of connection test. Its function is to employ it for diverse tests or to alter the current design. LCD, vehicle-mounted TV, industrial control medical equipment, etc, can be widely used in it. In the following Article, we will explain the Information of the Interposer board in detail.

What is an interposer in PCB?

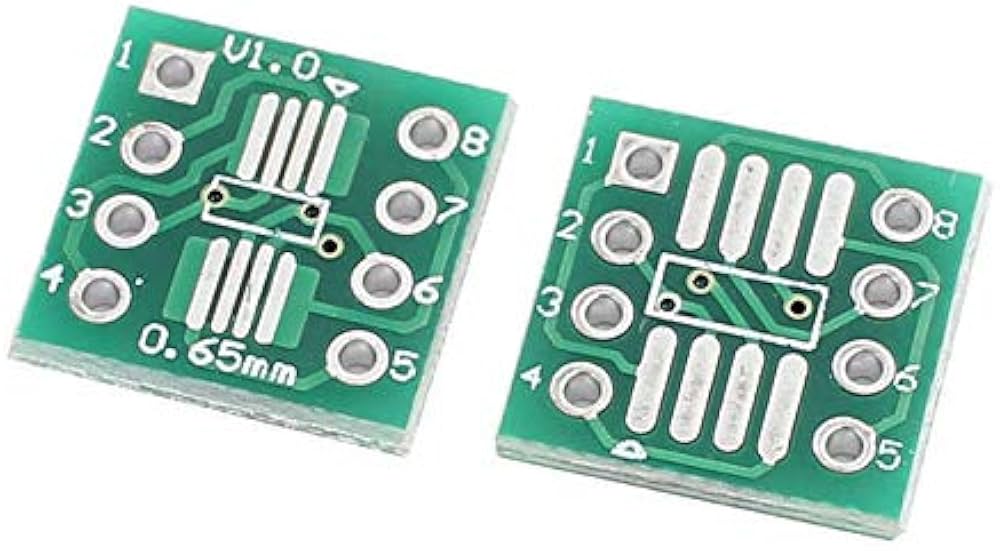

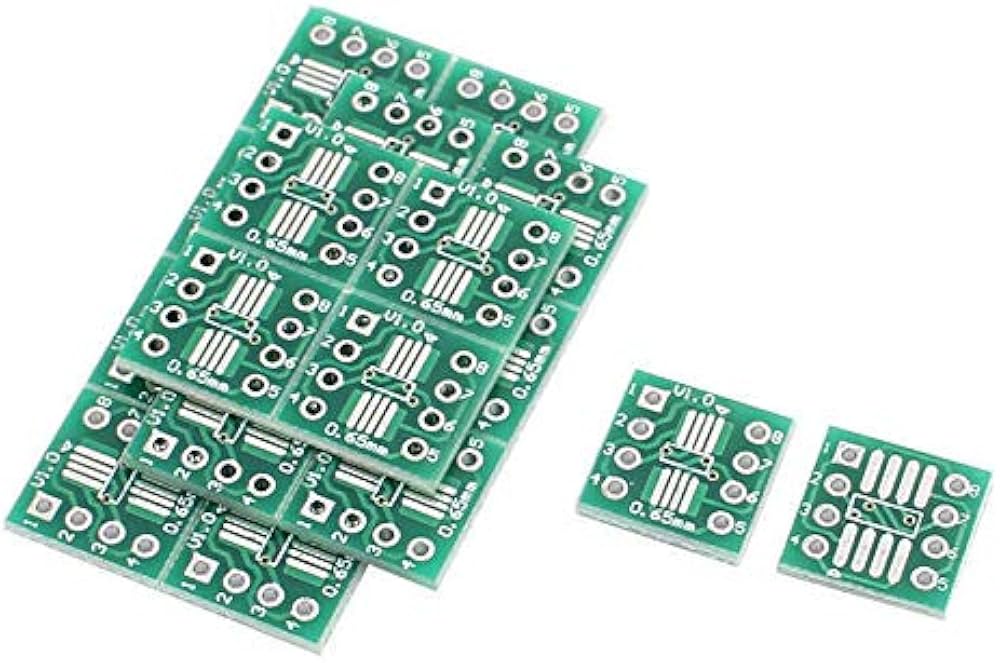

Interposer PCB is a kind of PCB commonly used in the production of portable communication devices such as mobile phones, computers, etc. These PCBs are employed in the connection of varied component parts. They are mainly located under the main PCB to simplify the production process of products.

They are used in fabrication because they permit the structure of intricate circuits to be established in a short time, without having to originate each constituent individually.

What role does the interposer board play?

The interposer board is mainly for joining one board or several boards together. It has many uses such as the electrical connection between the two boards, electromate shielding the two boards from interferences, as well as mechanical shielding of the two boards.

Many functions are:

- Distance between the board and the integrated circuits

- Contributes mechanized support for parts in the board

- Permits in the design of various types of PCB connectors like DIP and JEDEC.

- Offers signal routing to the ICs

Of what material is the interposer board chip made?

Interposers can be prepared from materials and in different ways, although they have some shared properties. Interposers are fabricated from copper-clad laminate (CCL), epoxy prepregs, glass fiber polyester reinforced (GFPRP), or other suitable materials. The CCL material is most often situated on the outer layers of the PCB, and holes are made using a laser through the material with subsequent plating. After the formation of an interposer, it is then placed on the bottom side of the PCB.

In addition, the interposer can be fabricated either manually or through the use of various fabrication technologies. The issue with making PCBs is that it still largely relies mostly on manual procedures such as PCB drilling, plating, lamination, and etching. Others are the drilling, platinizing, laminating, etching, and pick and place processes.

What consists of designing an interposer board?

It is relatively simple to design an interposer board. You have to choose what sort of interaction you want between the two circuits. Then, it would help if you calculated how much current each circuit requires. Looking at these requirements you have to select a layout that would be logical.

If your design incorporates features such as surface mount technology then that needs to be incorporated as well.